Over the past few decades, the manufacturing industry has undergone numerous major upheavals.

Right now, we are witnessing the dawning of the next era with Industry 4.0, boosted in Asia by China’s recently announced China 2020 vision, in which they outlined plans to adopt new technologies and industries, marking a shift away from traditional manufacturing.

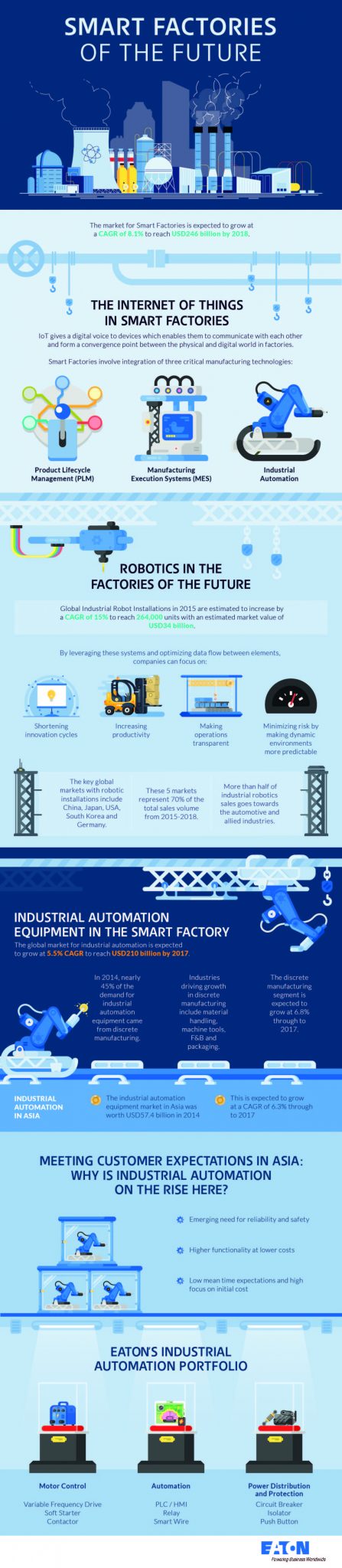

According to Eaton research on the machinery OEM segment, the global market for industrial automation is expected to grow at 5.5% CAGR to reach US$210 billion by 2017. This phenomenon is fast gaining traction, and it would be foolish not to carefully observe its development and re-assess existing strategies to fully capitalize on this new phase of manufacturing.

The importance of Industry 4.0

The way we do business has transformed. Disruptive business models and technology now have the power to make or break a company. In a way, constant change is now forcing businesses to “disrupt or be disrupted”. Like what the smartphone did to Nokia, and what Uber is doing to the taxi industry, Industry 4.0 can similarly render obsolete the company that doesn’t innovate and keep pace.

Industry 4.0 looks set to completely revolutionize the manufacturing industry through digitization and automation. Global consulting firm McKinsey & Company identified four drivers of this revolution: a rise in data volumes and connectivity, the emergence of analytics and business-intelligence capabilities, new forms of human-machine interaction such as touch interfaces, and improvements in transferring digital information to the physical world through technology like 3D printing and information modelling.

Big data and analytics can significantly increase productivity and quality in manufacturing, while the digitization of the physical world can drive collaboration and interoperability. Automation not only increases efficiency, but also serves to reduce the risk of human error and eliminate mundane tasks, ultimately driving the up-skilling of the manufacturing workforce.

In the past, elements in the industrial value chain such as design, planning and engineering were each implemented separately. In the age of Industry 4.0, new technology is bringing these elements together to work more seamlessly than ever.

Big data in manufacturing

The hype behind the Internet of Things (IoT) is massive, and for good reason. IoT gives a digital voice to machines, enabling them to communicate with each other about their position, condition, temperature, etc. By leveraging these systems and optimizing data flow between elements, companies can increase productivity, make operations transparent and minimize risk by making dynamic environments more predictable.

Digitizing manufacturing processes through IoT technology gives us access to information and data about our operations that we never before had. From this data, we can mine meaningful insights about our processes, identify issues such degradation or component wear, and gain greater transparency.

By bridging the gaps between our physical world and the digital one, we can engage and interact with our manufacturing operations more seamlessly and intuitively. The data can be translated to optimize factory processes and eliminate any areas of wastage or inefficiency, ultimately resulting in tangible businesses benefits.

Energy efficiency in the Smart Factory

For instance, energy efficiency is one of machine owners’ greatest challenges today, given rising energy bills and increasingly stringent regulatory requirements. Solutions that enable our customers to save energy, both in their machines as well as in their manufacturing facilities, will take center stage.

Energy efficiency can be achieved through energy measurement in manufacturing, which can help in identifying areas where energy could be saved. A technology such as Eaton’s Lean Power solution can deliver data in real time from the controller to the actuator/sensor, making all data related to electricity and energy consumption available to the entire machine and individual actuators. This information can be used on plants and machinery to optimize energy consumption, carry out preventative diagnostics and optimize processes.

New challenges of the smart factory

In the Smart Factory of today, many processes in manufacturing have been automated to reduce the level of human participation, and thereby error.

Future machines will be smarter, so we need to have more intelligent devices within these machines, making decisions on their own. One of Eaton’s top three solutions in the manufacturing segment, the SmartWire devices, enables businesses to adapt to the Smart Factory of today.

With the cost of labor rising in China today, manufacturers are seeking for more efficient way to improve their productivity and efficiency. Revolutionary products like Eaton’s SmartWire-DT can cut wiring efforts by 70% to achieve greater transparency and minimize downtime and manpower. This solution was adopted by in China Zoomlion, one of the largest manufacturers of construction solutions.

Smart devices are the key to powering a Smart Factory. This is especially relevant in Asian markets, which focus on high-end machinery OEM customers with complex machinery. To fully reap the benefits of automation in manufacturing, the industry must use smart technology and equipment strategically to reduce the complications arising from the implementation of such complex machinery, and the issues associated with these new systems.

New energy companies such as solar and wind power providers, which are gaining traction fast in energy-hungry China, rely on such high-end machinery. A device like Eaton’s solar inverter solution can reduce the maintenance cost associated with such equipment. By improving the overall reliability and

efficiency of these machines, smart devices have positioned themselves as an integral part of the manufacturing industry’s evolution.

Harnessing the potential of Industry 4.0

So what are the next steps for manufacturers to take? First and foremost, it is to advocate a digital mindset shift in the organization. Industry 4.0 is not a particular technology, or system, but rather an approach to doing business.

The next is to fully integrate automation into business strategies in order to realize its maximum potential. Automation cannot merely be an afterthought, but must be recognized as a legitimate business model that will help your organization stay relevant with the advent of Industry 4.0.

Lastly, acknowledge the importance of acquiring talent in this field, who can be the ambassadors of Industry 4.0 and lead the charge within the organization. Empowering employees with smart infrastructure and access to data will drive them embrace an enduring culture of productivity and innovation.

In taking a proactive stance to the evolution of the manufacturing industry, manufacturers can lead rather than follow the Industry 4.0 phenomenon.

(Attributed to Brian S. Brickhouse, President, Electrical Sector – Asia-Pacific Region, Eaton)